Novel 3D bioprinting device ‘prints’ skin-growing ink from patient cells in world-first clinical trials

Transforming how soft tissue wounds are treated, this groundbreaking medical device restores and regenerates layers of damaged skin – no stitches or skin grafts required.

A groundbreaking method to heal wounds such as burns, uses the patient’s own cells to create a scaffold for new skin to grow. This approach involves a technique called ‘3D bioprinting’, where living cells are combined with additional biomaterials to create a gel-like ‘bioink’. To deliver the bioink, a specialised surgical robot has been developed by biotechnology company, Inventia Life Science. The device is named LIGŌ, (from the Latin word “ligo”, which means “to bind”). The device places nano-sized droplets of bioink into a wound to support the regrowth of new skin layers that mimic naturally occurring skin tissue in the body.

Treating wounds in world first clinical trials

LIGŌ has been developed with funding support from two Medical Devices Fund grants awarded by the Office for Health and Medical Research. “We recently began a world-first clinical trial at Concord Repatriation General hospital, where LIGŌ is being used to treat patients with skin wounds such as a burn injury. Though this would normally require the harvesting of the patient’s cells for a skin graft, there is no need for this because the LIGŌ machine delivers the patient’s own cells directly to the wound site via the bio-ink,” says Dr Julio Ribeiro, founder of Inventia Life Science. “The approach is looking to revolutionise the way wounds are repaired. Our future aim is for this approach to also be used to treat more complex wounds.”

The LIGŌ device works a little like an inkjet printer, which uses a mixture of different colour combinations to create more options. “Similarly, we can load a mix of different biomaterials into the printer head then deliver this special matrix of regenerative biomaterials directly into a deep wound,” says Ribeiro. “This provides the necessary cell support structure to guide the regeneration of skin at the treatment site.”

More than skin deep

LIGŌ can be configured to deliver a tailored treatment for simple or more complex lesions. “Depending on the depth of the injury in a skin wound, different cell types and biomaterials can be printed to guide tissue regeneration of each unique skin layer,” Ribeiro explains.

In the future it is hoped that the device will be trialled to repair other skin injuries, including acute wounds from skin cancer excisions, as well as chronic wounds, such as pressure ulcers and foot ulcers caused by conditions such as diabetes. “It would also be possible to use LIGŌ to rapidly and precisely deliver other substances such as antimicrobial agents and drugs as well as growth factors to minimise infection risk and enhance healing,” Ribeiro points out. “Future applications could also extend into a range of regenerative medicine fields, to muscle, cartilage, or cornea repair.”

Minimising surgery and maximising patient outcomes

This bioprinting technique aims to improve patient outcomes, help people heal faster, reduce complications, and make regenerative treatments more accessible. “Current approaches to soft tissue reconstruction require large graft sites, complex surgical procedures or lengthy recovery times, which all impact the patient experience,” says Ribeiro. “LIGŌ’s ability to deliver biomaterials with unprecedented precision has the potential to mean better healing and ultimately better quality of life for patients.” As the length of time required in hospital is also reduced, the use of LIGŌ may help to lower healthcare costs.

Funding support from the Office for Medical Health and Research

Inventia received a Medical Devices Fund grant in 2021, which enabled LIGŌ to be developed, refined and introduced into a world-first clinical trial. “For example, we added a high-resolution vision system so that the clinician can accurately plan where and what to bioprint to form the new skin,” Ribeiro explains. “This made the procedure even more accurate and efficient.”

The second Medical Devices Fund grant, awarded in 2024, will enable the device to progress through commercial product development and regulatory approvals in Australia and the US.

Home Grown Innovation

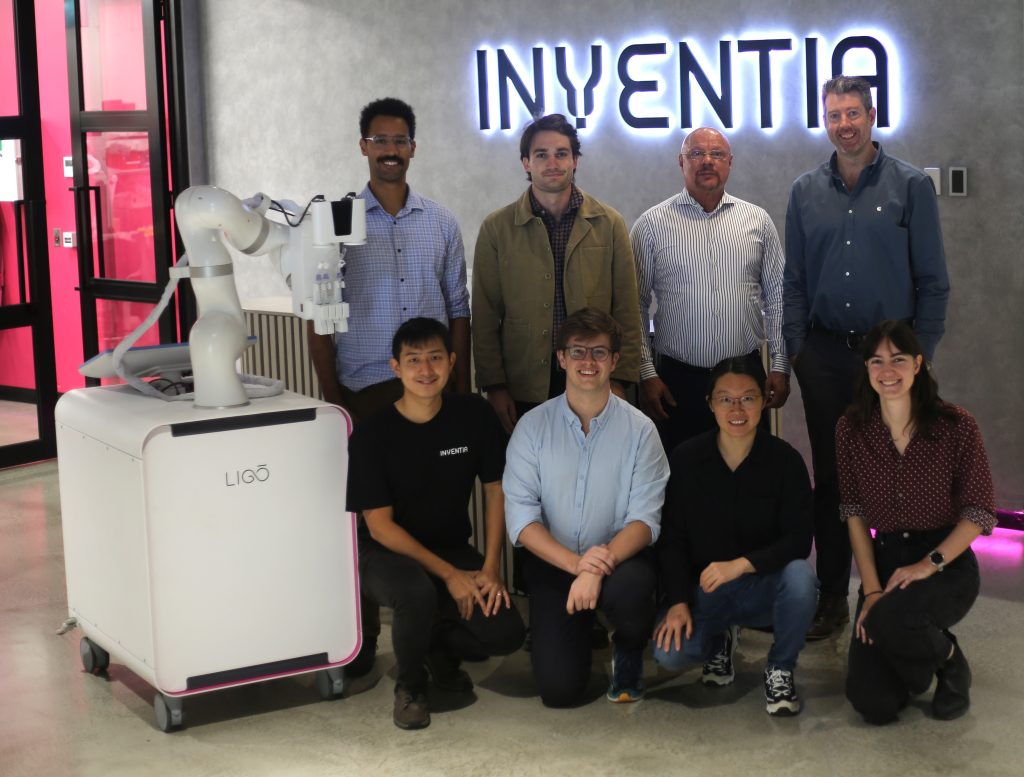

A small, dedicated team of seven expert engineers and scientists have designed, manufactured and matured the LIGŌ device from their Sydney headquarters in Alexandria. “Back in 2011, I had a ‘blue sky’ dream to be the first in the world to turn regenerative skin technology from a science fiction concept into reality,” says Ribeiro. “Over six very lean years I scraped by while I personally funded the development of that vision, which evolved into the LIGŌ medical device. Today, I’m proud to say that we have achieved that original vision, doing all of the work in Australia and paving the way for more groundbreaking clinical applications.”

Updated 2 months ago